The federal Occupational Safety and Health Administration (OSHA) ensures safe and healthful working conditions by establishing and enforcing workplace standards and regulations. Workplace safety is a crucial component of a successful business for large corporations and small business owners alike. By enacting policies and procedures aimed at protecting employees, companies can reduce financial risk, ensure legal compliance, and foster a positive and productive work environment.

Recordkeeping and annual reporting are critical compliance components of OSHA. Form 300A is a summary of workplace related injuries and illnesses recorded throughout the previous calendar year. This form must be completed and displayed by February 1st each year and remain visible to employees until April 30th. Injury and illness data must also be electronically submitted via OSHA’s Injury Tracking Application (ITA) portal by March 2nd. Adhering to OSHA reporting deadlines increases awareness of workplace safety records encouraging employers to take a proactive approach to identifying areas in need of improvement.

What is OSHA and Why Does It Matter?

In response to the growing concern over the staggering number of workplace injuries, illnesses, and fatalities, the Occupational Safety and Health Act was signed in to law in 1970. The creation of the Occupational Safety and Health Administration (OSHA) followed soon after. OSHA’s mission is to ensure that employees work in a safe and healthful environment by setting and enforcing standards, and by providing training, outreach, education, and assistance. These standards safeguard both employers and workers. A safe working environment limits accidents, injuries, and fatalities, which, in turn, fosters a high morale, loyal, and productive workforce. Safe workplaces benefit an employer’s profit margin as well by reducing costly workers’ compensation claims and medical bills, decreasing interruptions in business operations, and lowering the risk of damage to equipment.

The Importance of Injury and Illness Prevention

Preventing workplace accidents is possible with a few key proactive measures.

- Identify risks and hazards throughout the workplace and establish safety procedures to address them.

- Make sure safety protocols are easy to access during an emergency.

- Develop and communicate a procedure for workers to report any injuries, illnesses, hazards, or safety and health concerns.

- Supply necessary personal protective equipment and stay up-to-date with evolving safety equipment standards.

- Provide training to workers about how to avoid accidents, use equipment properly, address hazards, and respond to emergencies.

- Mandate regular safety education with OSHA’s assistance. OSHA Training Institute Education Centers offer occupational safety and health training across the country to both the public and private sectors in all industries.

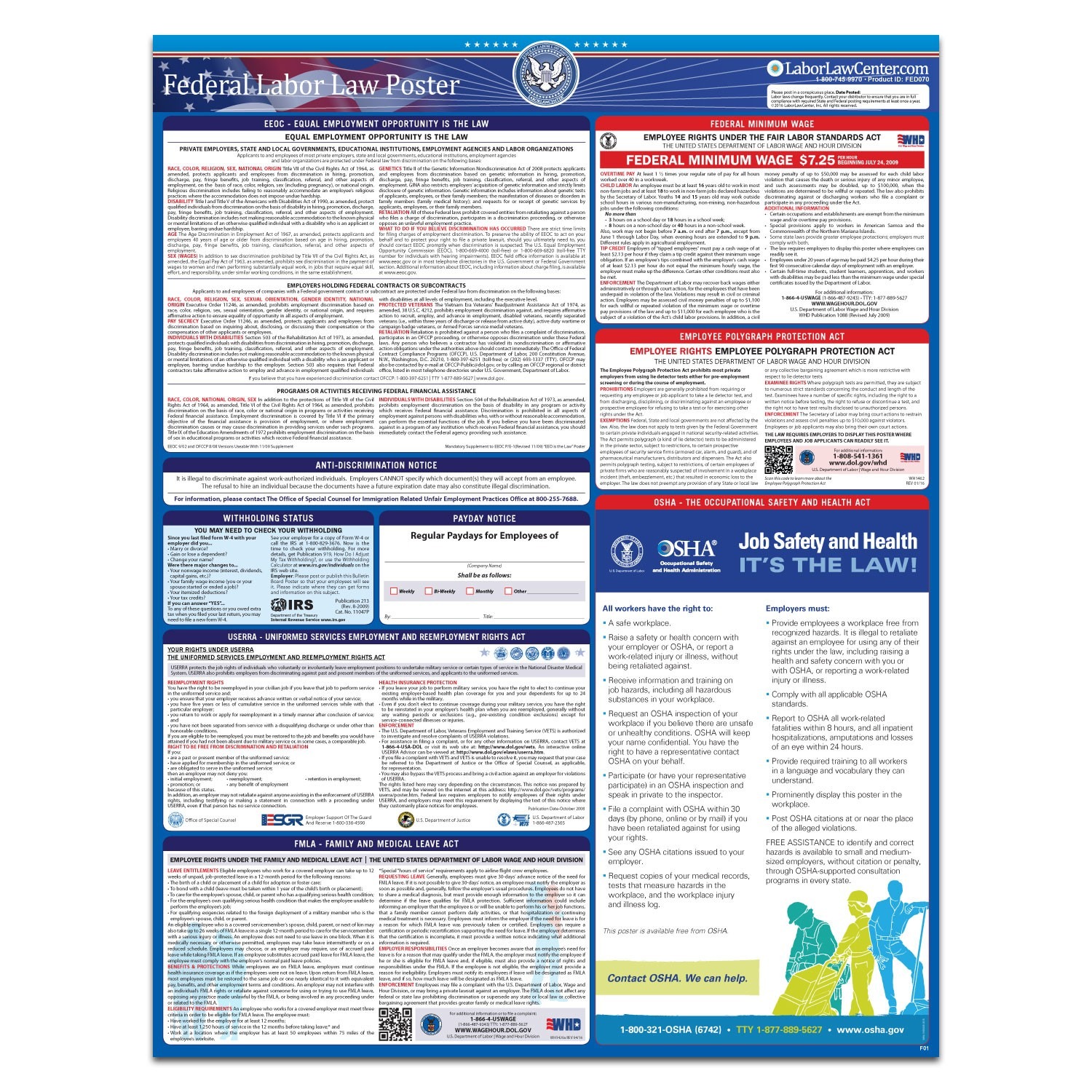

- Continually reinforce commitment to a safe work environment by displaying OSHA’s “Job Safety and Health: It’s the Law” poster and any industry applicable workplace safety and health posters in a location visible to workers.

Top 10 Most Frequently Cited OSHA Standards

OSHA publishes a list of the most commonly cited violations for all industries observed during workplace inspections. This list represents areas where businesses often lack adequate safety measures and provides an opportunity for employers to identify and fix recognized hazards in accordance to these and all OSHA standards.

- Fall Protection

Fall protection has been the most cited OSHA violation for 14 years. It mainly applies to the construction industry since workers are often exposed to height related hazards such as unguarded edges, unsecured holes, scaffolding, ladders, and inadequate fall protection measures.

- Hazard Communication

Despite OSHA’s Hazard Communication Standard, many employers fail to properly communicate information about chemicals in the workplace and their associated risks to their workforce. Inadequate labeling, insufficient safety data sheets, and lack of hazardous chemicals training increase the risk of exposure to harmful chemicals.

- Ladders

OSHA regulations require that ladders in the workplace must be free from defects and used in a safe manner including secure positioning and stability. Violations typically include improperly positioned and secured ladders, ladder usage in ways for which they were not designed, carrying too heavy objects or loads, and ladders with broken or corroded components.

- Scaffolding

Specific design, construction, and erection requirements for scaffolding are provided in OSHA’s Scaffolding Standard. Common hazards associated with scaffolds include failing to comply with capacity requirements, platform construction, fall prevention measures, and falling object protection standards.

- Powered Industrial Trucks

Powered industrial trucks, commonly referred to as forklifts, pallet jacks, or similar equipment, are often used in warehouses, factories, and construction sites. Operator training and certification, equipment inspection and maintenance, and proper safety measures for the handling of objects or loads are imperative to safe operations. Common violations include incomplete or incorrect label information, reckless use, carrying unsupported or too heavy loads, and not having the proper education and training for workers.

- Control of Hazardous Energy

More commonly known as Lockout/Tagout (LOTO), workers servicing or maintaining machines or equipment are at risk of injury or death if proper procedures aren’t in place and followed to prevent hazardous energy from being released. Employers enacting poor energy control programs and procedures, failing to conduct periodic inspections, and providing insufficient training and communication to workers constitute the top offenders.

- Respiratory Protection

Hazardous airborne substances, such as dust, fumes, vapors, or gases, require employers to establish a respiratory protection program which ensures proper safety equipment and necessary training is provided to workers. Violations occur when employers fail to provide sufficient training and ensure the correct use of safety equipment, specifically respirators.

- Fall Protection Training

While fall protection is the most cited OSHA violation, considerable violations occur for lack of fall protection training. Any worker who may be exposed to fall hazards must receive training in the nature of fall hazards in the work area, correct use and maintenance of fall protection systems, proper monitoring of safety systems, and the role of the employee in fall protection plans. OSHA also requires workers to be trained in a language they understand, which may be a reason for some training citations.

- Eye and Face Protection

Personal Protective Equipment (PPE) for the eyes and face is designed to prevent or lessen the severity of injuries to workers when they are exposed to eye or face hazards such as flying particles, molten metal, liquid chemicals, acids or caustic liquids, chemical gases or vapors, or potentially injurious light radiation. Workers must be informed of the different types of eye and face protection equipment that are available and properly trained on how to use the equipment. Many citations occur when employers neglect to provide appropriate PPE and fail to ensure it is used correctly.

- Machinery and Machine Guarding

Machine guarding refers to protecting workers from moving parts, flying debris, and other hazards associated with machinery. The most common violation accounts for the majority of citations, improper types of guarding.

OSHA Penalties: What’s at Stake?

The penalties for non-compliance with OSHA standards and regulations can quickly add up, affecting a company’s bottom line. Serious violations, violations with a substantial probability that a hazardous condition will result in serious harm or death, and other-than-serious violations, those less likely to result in serious harm but still pose safety risks, carry fines up to $16,550 per violation. Failure to correct a violation within the timeframe set by OSHA will cost employers $16,550 per day. Moreover, a willful violation, meaning when an employer knows of a hazardous condition and intentionally disregards it, can incur a fine up to $165,514 per violation. In cases of willful violations that result in severe injury or death, OSHA may pursue criminal charges against the employer resulting in more significant fines and possible imprisonment.

The financial impact on employers with poor safety standards in the workplace is not always direct. Reduced employee morale and reputation damage can impose significant harm to a company. When employees feel their safety is being compromised and not taken seriously, it can lead to low employee morale, reduced productivity, and high turnover rates. In today’s digital age, these employees can easily share their concerns with others, whether co-workers, customers and clients, and even news outlets. The damage to a company’s reputation can result in difficulty in attracting and retaining talented workers as well as acquiring and keeping customers and clients. In fact, the reputation damage could be costlier than the OSHA fines.

Furthermore, in the year before OSHA was established, there were approximately 14,000 workplace fatalities and 2.5 million workplace injuries in the U.S. After 50 years of OSHA standards, a total of 5,283 fatal workplace injuries and 2.6 million injury and illness cases were reported in 2023. Though injury and illness numbers are similar, the significant decrease in the number of fatalities is a testament to the importance of OSHA’s mission.

OSHA Posters and Signage Can Help

The most effective advice to all companies – Don’t wait for something bad to happen. Take the time now to build a culture that focuses on safety. Implement a safety and health program that includes leadership and values worker participation to create a systematic approach to addressing workplace hazards.

Workplace posters are an essential tool for employers in maintaining compliance with safety regulations. OSHA’s “Job Safety and Health: It’s the Law” workplace poster informs workers of their rights to work in an environment free from recognized hazards, report unsafe conditions without fear of retaliation, and request an OSHA inspection. All covered employers are required to conspicuously display the poster in their workplace where workers can view it. Failure to do so can result in fines and penalties.

Safety and health posters provide daily reminders to employees about workplace hazards, best practices to avoid injury and stay healthy, and how to report unsafe conditions. Displaying posters related to industry-specific hazards reminds employees of the risks associated with their job and reduces workplace injuries. Posters related to reporting hazards and conveying emergency action plans ensures employees are aware of correct safety procedures. Further, general health posters encourage employees to engage in healthy habits at work.

Since most people process images faster than text, posters using attractive colors, bold text, and captivating graphics quickly capture a worker’s attention and convey important messages effectively. Placing visual aids in strategic locations ensures the messages reach all employees. Workplace posters reinforce a culture of safety by providing continuous awareness of clear and accessible workplace safety information.

Actionable Tips for Businesses

Maintaining OSHA compliance can seem an arduous task. Here are 4 tips to help you remain OSHA compliant.

- Conduct Safety Audits

- Identify and correct detected hazards

- Maintain records of inspections and corrective actions taken

- Update Safety Plans

- Ensure your safety plan is comprehensive including risk assessments, safety measures and procedures, and emergency protocols

- Distribute safety plan to employees

- Provide Employee Training

- Identify all necessary training for each category of employees

- Train employees on hazard recognition, safety practices, and emergency response

- Document safety training sessions including employee attendance

- Know Your OSHA Standards

- Make sure you’re aware of all the OSHA standards that apply to your industry

- Regularly review OSHA standards to ensure up-to-date information

Communication is essential in maintaining OSHA compliance. Ensuring workers are informed of potential risks, safety requirements, and incident response protocols are imperative to a safe workplace. Make sure a clear communication procedure is in place for all safety and health programs. Supplement communication procedures with OSHA and other safety and health related workplace posters to quickly and easily convey important information.

An OSHA-compliant business stays informed, complies with safety and health standards, and invests in valuable tools like OSHA posters to create and maintain a safe and healthful work environment. Equip your business with quality resources and expertise by partnering with a trusted and reliable labor law compliance company like LaborLawCenter. LaborLawCenter provides all in one state labor law posters, which include the required OSHA poster, customized compliance solutions, automatic labor law poster replacement services, and other federal and state mandated labor law posters.